Feature

Carbon blocks, flywheels, and new “alternative” energy storage

“Alternative” energy storage covers a wide range of systems, all of which are becoming more cost-efficient and widespread. Nnamdi Anyadike looks at the buzz around carbon blocks, flywheels and thermal storage systems.

Cement could act as energy storage. Credit: Researchers/MIT

Some time ago, renewables were known as “alternative power”, considered niche for daring to run against the conventions of gas and oil. Now these are mainstream, but the “alternative” label still holds some weight in the power storage industry. Battery farms act as “mainstream” energy storage devices, but “alternative energy storage” devices promise cheaper, more efficient, or more bespoke systems. Recent research has provided new solutions to the question of grid balancing, and given “promising” innovations in how consumers can build energy storage into their lives.

Building super-capacitors into infrastructure

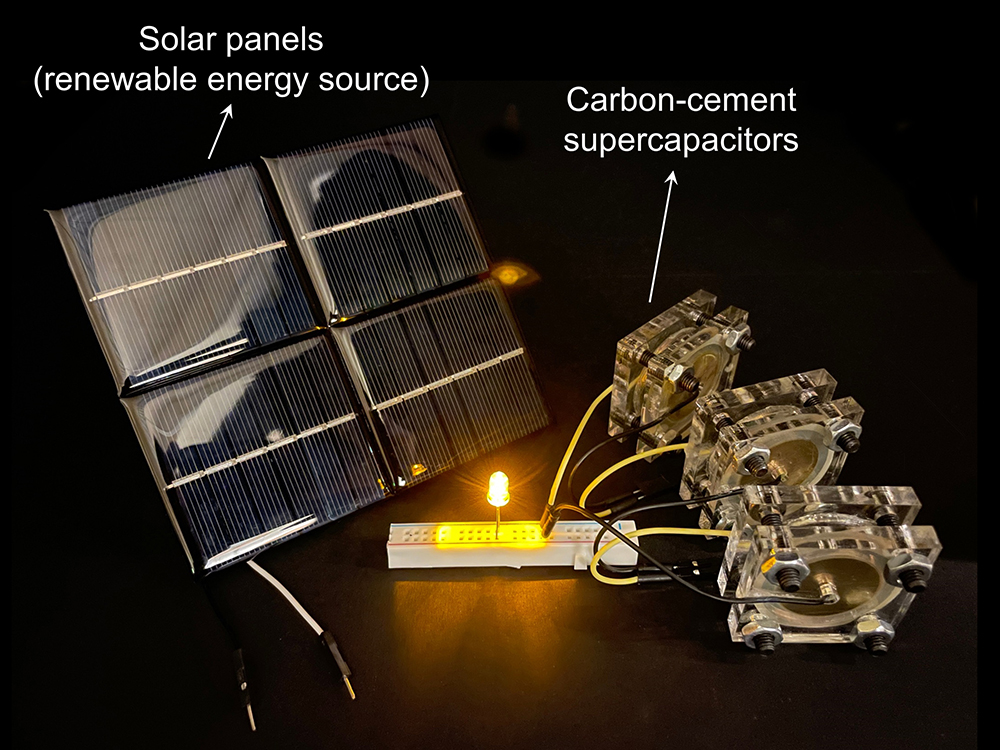

Researchers at the Massachusetts Institute of Technology are working on a storage medium using cement, water and carbon black to create a solid super-capacitor . Professors including Admir Masic, Franz-Josef Ulm and Yang-Shao Horn, and others at the Wyss Institute for Biologically Inspired Engineering claim that the super-capacitor system could transform intermittent renewable energy. It could do this by allowing energy networks to remain stable despite fluctuations in renewable energy supply from solar, wind, and tidal power.

Masic says: “You have the most-used manmade material in the world, cement, combined with carbon black. When you combine them in a specific manner, you come up with a conductive nano-composite and that’s when things get really interesting.” Ulm says that carbon black super-capacitors have great potential to aid in the world’s transition to renewable energy: “Existing batteries are too expensive and mostly rely on materials such as lithium whose supply is limited. That’s where our technology is extremely promising, because cement is ubiquitous.”

Cement supercapacitors in action. Credit: Researchers/MIT

Solid super-capacitors would allow for power storage to be built into the concrete foundation of a house. From here they could store a full day’s worth of energy while adding little, or no, cost to the foundation. However, while adding more carbon black allows the super-capacitor to store more energy, it makes the concrete mix slightly weaker. This means the system is only useful for applications where the concrete is not playing a structural role, or where the full strength-potential of concrete is not required. The MIT team calculated that a block of nanocarbon black-doped concrete equivalent to a cube about 3.5m across would have enough capacity to store about 10kWh of energy. This is considered the average daily electricity usage for a household. Super-capacitors could also be placed under concrete roadways to provide contactless recharging for electric cars as they travel over the road.

Antora and ETS develop storage blocks

In California, a project team at Antora Energy is developing a similar thermal carbon block-based energy storage system. The project has received early-stage funding from the US Department of Energy’s ARPA-E research body, through its Duration Addition to Electricity Storage (DAYS) programme. More recently, it received funding from venture capitalists and the California Energy Commission until June 2024. Antora’s technology uses wind and solar electricity to heat up blocks of solid carbon to temperatures above 1500°C. This heat can then be used in high-temperature industrial processes such as steel and cement. Antora can also convert light from these glowing-hot carbon blocks back into electricity using its thermophotovoltaic (TPV) technology. These TPV panels are similar to regular photovoltaic solar panels, but specifically designed to efficiently use heat radiated by the blocks.

Another company, Boston-based Electrified Thermal Solutions (ETS) hopes to build a similar thermal storage system to Antora’s, but using conductive ceramic blocks. Its vision is to use renewable electricity to heat up the blocks to over 1,500°C and then turn it back in to electricity for the grid when needed. But in order to beat the cost of energy storage from natural gas, solar and wind plants, this system would have to cost around $10/kWh . The company is confident that its patented Joule Hive heating system will meet that price, even beating the cost efficiency of lithium-ion batteries, which MIT economists estimate will reach $20/kWh in 2030.

The technology leverages a proprietary process that enables the electric heating of “firebricks”. These can also be stacked into larger electrified heating systems that can deliver, at maximum, several gigawatts of heat to industrial furnaces, boilers, kilns or power turbines, with storage durations of several days. Last year the company received $4.5 million in initial financing innovation and venture capital funds. This funding is being leveraged to grow ETS’ team, while building out a large laboratory prototype outside Boston, MA. This will be followed by a multi-megawatt demonstration plant.

Flywheel technology – an energy storage alternative

Thermal energy storage by means of carbon blocks, however, is just one of the “alternative” energy storage technologies that are becoming available. Flywheels have been used to regulate energy supplies for centuries, conserving intermittent power as momentum on a heavy spinning mass connected to a motor. This can then be converted back in to electrical energy by the generator when required. While they are frequently used with steam engines, their modern use still requires development and commercialisation efforts. Flywheels are said to have several advantages over other energy storage technologies, including efficiency a lifespan of up to 20 years and fast response times.

In the US, several companies are involved in developing the technology. Massachusetts-based Beacon Power’s carbon fibre flywheel is a modular system, configurable from 100kW to multi-MW systems. Meanwhile, California’s Amber Kinetics manufactures long-duration flywheel energy storage systems claims that this is the first commercialised, four-hour discharge, long-duration solution. It is powered by advanced technology that stores 32kWh of energy in a two-ton steel rotor. “But individual flywheels can be scaled up to tens or even hundreds of megawatts,” a company statement says. Just as heat storage devices lose energy by radiating heat, flywheels experience friction that can only be offset through regular maintenance. Another challenge comes with the speed of rotation, which limits the type of materials that can be used to strong and lightweight materials like carbon fibre, which can make the flywheel expensive to manufacture.

Flywheels have regulated power in mechanical systems for centuries. Credit: Cadeno via Shutterstock

Elsewhere, Canadian company Temporal Power’s proprietary system is sized for utility-scale projects, typically ranging from 2MW to 100MW, or larger. The company claims that the highest-energy flywheels in the world, with unmatched power output of 500kW per flywheel.

Both flywheel systems and thermal systems create mediums for energy storage, but some technologies straddle the boundary between storage and generation, using natural mediums for energy storage. Heat pumps promise to draw heat from natural heat sources, and can use heat energy without further conversion. In Germany, RheinEnergie has unveiled plans for a large-scale heat pump that will use the energy of the Rhine River to deliver 150MW of heat output. The heat will be made available to the district heating network in central Cologne to heat around 30,000 residential units. Construction is scheduled to start early next year and commissioning is planned for early 2027. Another 50MW heat pump will later be installed in the Merkenich district in northern Cologne.

Similarly, geothermal power uses heat within the earth, and some storage projects have used this principle in reverse. In Hamburg, a pilot project by Siemens Gamesa stores 130MWh of energy for up to a week by heating natural volcanic rock to 600°C, at a cost of €100/kWh. The company markets it as “the revival of a 200-year-old idea”, saying: “Theoretically there is no upper limit to the potential size of a project. Based on the knowledge we have today, a 1GWh storage project could be commissioned as early as 2025.” The company has said that, after testing finishes, they will likely work with a partner to build out this planned 1GWh plant.