CONTACT BOWMAN

VISIT BOWMAN WEBSITE

To learn more about the ETC system and how Bowman can help you, please get in touch or visit bowmanpower.com.

UNLEASH

YOUR GENSET'S

POTENTIAL

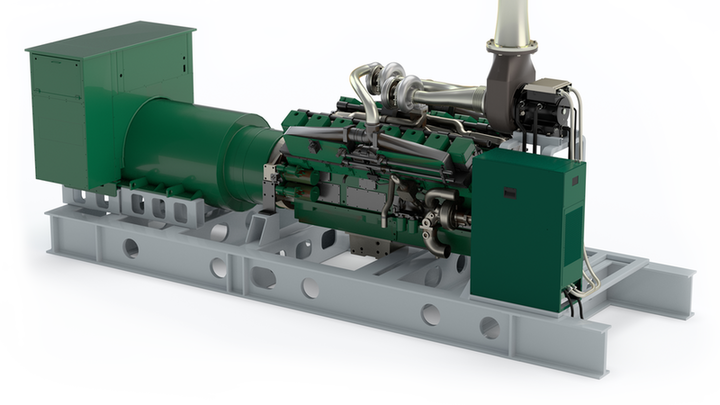

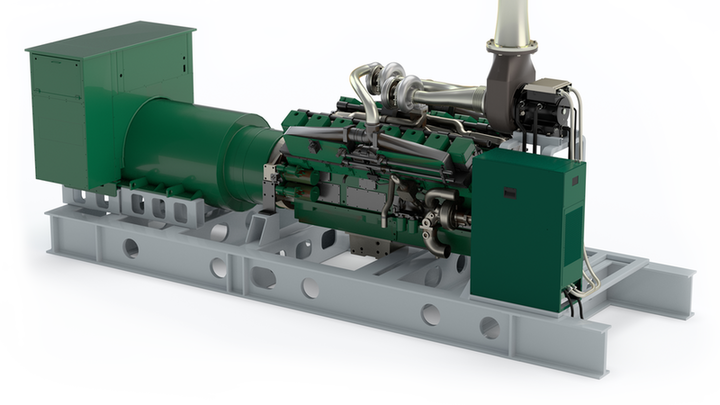

You can’t always change your genset, but with our Electric Turbo Compounding (ETC) systems you can realise its true potential. By converting waste exhaust energy into grid-quality electrical power, our ETC systems improve power density and fuel efficiency, whilst reducing emissions.

Compatible with the majority of diesel and gas-fuelled gensets in the 150KW-2.5MW range, our patented and proven technology is the ideal way to make your genset run better than ever before.

Click here to find out how

ETC can help you.

HOW ETC CAN HELP

Click on a circle to learn more

1

Generate additional power

Reduce CO2 emissions

Quick payback

Achieve competitive advantage

Reduce UHC emissions

Increase efficiency and reduce fuel consumption

Achieve faster

start-up

3

7

4

5

2

6

ADDITIONAL POWER

For customers wishing to generate additional power for the same fuel, we can achieve up to 10% more power.

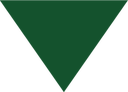

Our ETC system uses a high speed turbo generator to recover a proportion of the engine’s exhaust energy. This is then converted directly to grid quality electricity.

Thanks to our patented power electronics unit, the energy created by our ETC system is converted to 3 phase AC grid standard (50/60Hz) output. With broad grid code compliance the power generated can be used for: site ancillary loads, remote community power, industrial loads, grid export or even for offsetting the engine parasitic (ancillary plant) losses.

INCREASED EFFICIENCY

An ETC-equipped genset is more efficient than a base model, which is why we typically reduce fuel consumption by 4-7%.

By recovering waste energy from the engine exhaust to generate power, our ETC systems provide an improvement to the overall efficiency of the genset, enabling end-users to reduce the amount of fuel burned.

This increase in electrical efficiency and power density drastically reduces the cost per kWe generated.

Our technology is proven on a number of fuel types including diesel, natural gas, landfill gas, biogas, waste coal mine gas, syngas and biodiesel.

FAST PAYBACK

Our ETC customers have achieved payback in as little as 12 months.

Through extensive R&D we have been able to reduce the cost of our ETC system by 50%, making it more cost effective than ever.

For typical genset installations, the addition of an ETC system does not add any significant cost in terms of unit cost per kW. The increase in power more than offsets the cost of this system. This results in a more economical genset with quick payback periods.

With low maintenance costs, high reliability and minimal engine downtime the running costs of ETC are kept low, whilst quality is assured.

This is why we’ve consistently demonstrated strong return on investment and internal rate of return for our customers across a number of sectors.

REDUCED CO2

We can achieve an up to 23% reduction in greenhouse gas emissions (CO2 and CH4).

In fact, we’ve reduced CO2 emissions by more than 320,000 tonnes across our installed systems.

By enabling our customers to reduce fuel consumption, the same power can be created with less CO2 emissions. Or, for customers who want more power for the same fuel, the additional power can be created without any increase in associated CO2 emissions.

ETC is a proven and reliable way for companies with clean energy policies and emissions targets to achieve their goals.

REDUCED UHC EMISSIONS

We can achieve an up to 40% reduction in unburnt hydrocarbon (UHC) / volatile organic compound emissions.

Typical UHC emissions from a natural gas engine can vary between 1-4% of the fuel supplied. UHC emissions from alternate fuel engines such as biogas or landfill gas can be even higher, due to the effects of both CO2 and power cylinder deposits on combustion.

Through applying ETC technology, we can significantly reduce these emissions as well as fuel consumption. This is achieved by reducing the scavenging pressure. This almost entirely eliminates fuel short circuiting due to scavenging and reduces the flow of UHC rich residual gases from the piston and liner/gasket crevices during valve overlap to the exhaust.

The increase in power generated and fuel saved by the ETC system significantly exceeds any losses in engine efficiency due to the reduction in scavenging pressure.

FASTER START UP

Cold and preheated engine start times are significantly reduced with load ramp times reduced by up to 50% for ETC optimised engines.

This offers considerable benefits for users of gensets in the primary/secondary frequency reserve markets and datacenters.

Benefits include:

- Less fuel used per engine start

- Reduced turbo lag

- Reduced NOx emissions

- Lower PM emissions

- Lower thermal stress

What’s more, the ETC system delivers improved efficiency without increasing service or maintenance requirements. Whether through installation or ongoing performance we keep any downtime to a minimum.

ACHIEVE competitive advantage

We supply in to three core markets, enabling our customers to achieve competitive advantage, helping:

Engine and generator OEMs to differentiate their products and improve engine efficiency without the need to undergo extensive genset modifications and R&D projects. We have also partnered with OEMs on engine specific trials and market studies.

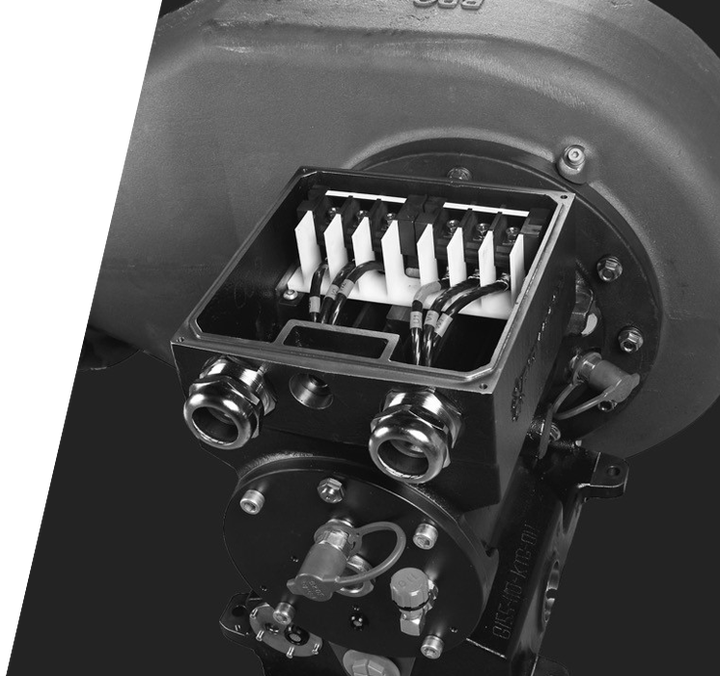

Rental companies to provide customers with an enhanced rental offering, reducing the number of gensets required along with logistical and operational costs. Thanks to ETC’s compact installation size, this also won’t impact the footprint of a standard 40ft rental container.

Independent power producers to run highly efficient plants and improve profitability whilst meeting emissions and contractual efficiency targets. With a long product life and cost-effective payback period we can support you over the lifetime of your contracts.

HOW ETC CAN HELP

Click on a circles to learn more

1

Generate additional power

Reduce CO2 emissions

Quick payback

Achieve competitive advantage

Reduce UHC emissions

Increase efficiency and reduce fuel consumption

Achieve faster

start-up

3

7

4

5

2

6

ADDITIONAL POWER

For customers wishing to generate additional power for the same fuel, we can achieve up to 10% more power.

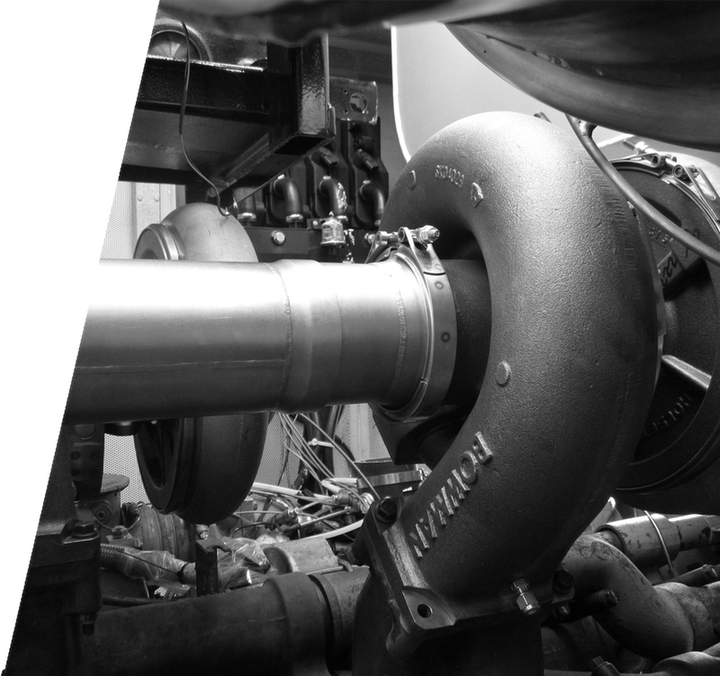

Our ETC system uses a high speed turbo generator to recover a proportion of the engine’s exhaust energy. This is then converted directly to grid quality electricity.

Thanks to our patented power electronics unit, the energy created by our ETC system is converted to 3 phase AC grid standard (50/60Hz) output. With broad grid code compliance the power generated can be used for: site ancillary loads, remote community power, industrial loads, grid export or even for offsetting the engine parasitic (ancillary plant) losses.

INCREASED EFFICIENCY

An ETC-equipped genset is more efficient than a base model, which is why we typically reduce fuel consumption by 4-7%.

By recovering waste energy from the engine exhaust to generate power, our ETC systems provide an improvement to the overall efficiency of the genset, enabling end-users to reduce the amount of fuel burned.

This increase in electrical efficiency and power density drastically reduces the cost per kWe generated.

Our technology is proven on a number of fuel types including diesel, natural gas, landfill gas, biogas, waste coal mine gas, syngas and biodiesel.

FAST PAYBACK

Our ETC customers have achieved payback in as little as 12 months.

Through extensive R&D we have been able to reduce the cost of our ETC system by 50%, making it more cost effective than ever.

For typical genset installations, the addition of an ETC system does not add any significant cost in terms of unit cost per kW. The increase in power more than offsets the cost of this system. This results in a more economical genset with quick payback periods.

With low maintenance costs, high reliability and minimal engine downtime the running costs of ETC are kept low, whilst quality is assured.

This is why we’ve consistently demonstrated strong return on investment and internal rate of return for our customers across a number of sectors.

REDUCED CO2

We can achieve an up to 23% reduction in greenhouse gas emissions (CO2 and CH4).

In fact, we’ve reduced CO2 emissions by more than 320,000 tonnes across our installed systems.

By enabling our customers to reduce fuel consumption, the same power can be created with less CO2 emissions. Or, for customers who want more power for the same fuel, the additional power can be created without any increase in associated CO2 emissions.

ETC is a proven and reliable way for companies with clean energy policies and emissions targets to achieve their goals.

REDUCED UHC EMISSIONS

We can achieve an up to 40% reduction in unburnt hydrocarbon (UHC) / volatile organic compound emissions.

Typical UHC emissions from a natural gas engine can vary between 1-4% of the fuel supplied. UHC emissions from alternate fuel engines such as biogas or landfill gas can be even higher, due to the effects of both CO2 and power cylinder deposits on combustion.

Through applying ETC technology, we can significantly reduce these emissions as well as fuel consumption. This is achieved by reducing the scavenging pressure. This almost entirely eliminates fuel short circuiting due to scavenging and reduces the flow of UHC rich residual gases from the piston and liner/gasket crevices during valve overlap to the exhaust.

The increase in power generated and fuel saved by the ETC system significantly exceeds any losses in engine efficiency due to the reduction in scavenging pressure.

FASTER START UP

Cold and preheated engine start times are significantly reduced with load ramp times reduced by up to 50% for ETC optimised engines.

This offers considerable benefits for users of gensets in the primary/secondary frequency reserve markets and datacenters.

Benefits include:

- Less fuel used per engine start

- Reduced turbo lag

- Reduced NOx emissions

- Lower PM emissions

- Lower thermal stress

What’s more, the ETC system delivers improved efficiency without increasing service or maintenance requirements. Whether through installation or ongoing performance we keep any downtime to a minimum.

ACHIEVE competitive advantage

We supply in to three core markets, enabling our customers to achieve competitive advantage, helping:

Engine and generator OEMs to differentiate their products and improve engine efficiency without the need to undergo extensive genset modifications and R&D projects. We have also partnered with OEMs on engine specific trials and market studies.

Rental companies to provide customers with an enhanced rental offering, reducing the number of gensets required along with logistical and operational costs. Thanks to ETC’s compact installation size, this also won’t impact the footprint of a standard 40ft rental container.

Independent power producers to run highly efficient plants and improve profitability whilst meeting emissions and contractual efficiency targets. With a long product life and cost-effective payback period we can support you over the lifetime of your contracts.

WHY ETC?

Our ETC solution has completed over 22 million operating hours on engines from over 10 OEMs, burning various gas and liquid fuels.

We’ve been improving on this technology for 15 years, and our new third generation solution is more cost-effective, reliable and easy to install than ever.

View “What is ETC” Video

ESTABLISHED TECHNOLOGY

15+

Years of R&D

800+

Systems sold and in operation

22m+

Field hours of operation

680+

GWh of free energy generated to date

300,000

Tonnes of CO2

saved

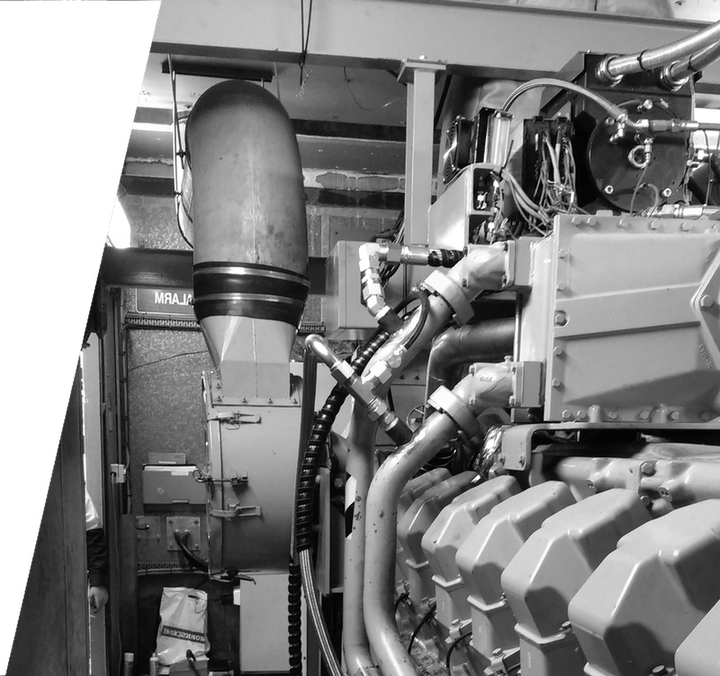

COMPATIBILITY

We’ve worked closely with engine and genset original equipment manufacturers (OEMs) to ensure maximum efficiency and compatibility.

Our ETC systems have already been proven on:

• CAT

• Cummins

• Jenbacher (INNIO)

• MAN

• Mitsubishi

• MTU

• Scania

• Volvo

• Wärtsilä

Compatible with:

• The majority of diesel and gas fueled gensets

• New and retrofit applications

• Open and containerised gensets

• 600kW-1100kW range as a single system

• 1100kW-2,500kW range as a twin system

• Bespoke solutions up to 20,000kW

Go to Top

CONTACT BOWMAN

VISIT BOWMAN WEBSITE

To learn more about the ETC system and how Bowman can help you, please get in touch or visit bowmanpower.com.

CONTACT BOWMAN

VISIT BOWMAN WEBSITE

To learn more about the ETC system and how Bowman can help you, please get in touch or visit bowmanpower.com.