Advanced formula provides superior oxidation stability & deposit control for gas combustion turbines.

Formulated specifically for use in gas combustion turbines, Endure™ Turbine Oil (6481-6482) features a unique blend of highly refined base oils and proprietary additive technology. Its advanced formula provides superior oxidative and thermal stability while preventing varnish and sludge formation on critical surfaces. Endure Turbine Oil ensures long-lasting, trouble-free performance in gas combustion turbines, minimizing unplanned outages and maximizing uptime.

Oil problems are estimated to be the cause of nearly one-fifth of all forced turbine outages, according to A Comprehensive Guide to Industrial Turbine Lubricants by Afton Chemical Corp. Oxidation and thermal degradation are chief among the various mechanisms inside a turbine system that can result in degradation of in-service oil.

Endure Turbine Oil Withstands

Oxidation 3X Longer

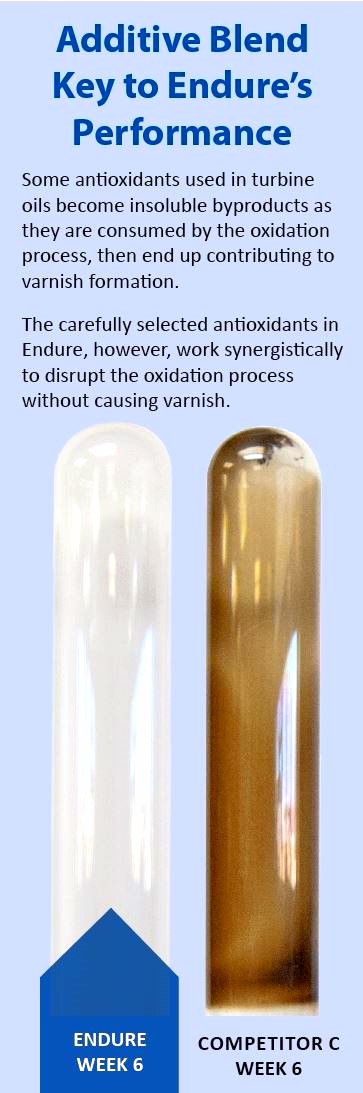

As turbine oil begins to oxidize, byproducts form and start consuming the oil’s antioxidant additives. As oxidation progresses, more and more of these byproducts form and begin to coalesce into larger insoluble bodies. With time, these insoluble bodies plate out as varnish in cooler areas of the turbine system, such as sumps, heat exchangers and hydraulic controls. The varnish can lead to serious situations such as trips or failure to start.

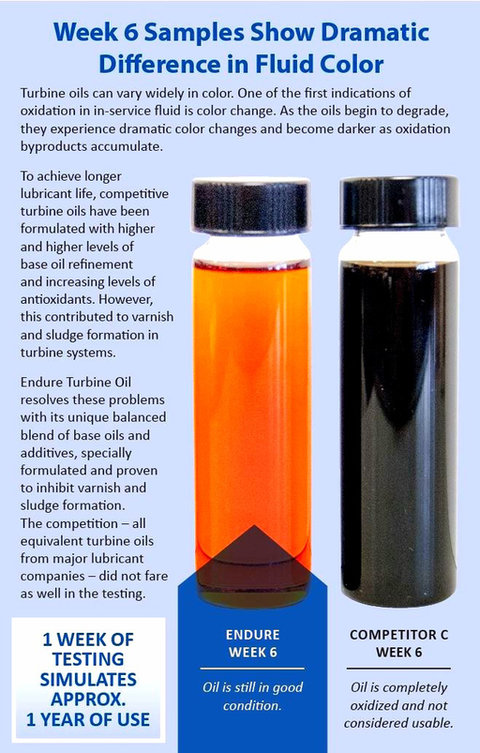

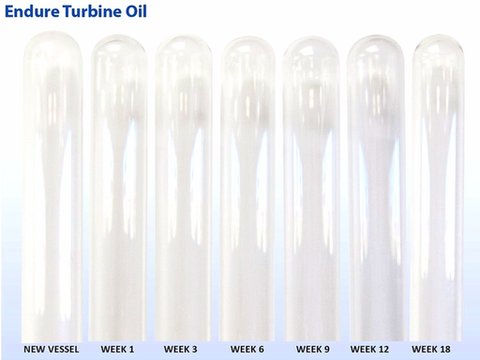

To ensure that its turbine oil would withstand oxidation and avoid these problems for its customers, Lubrication Engineers developed a turbine oil varnish test – TOVT. The purpose of this test is to study the oxidative behaviour of new turbine oils in an accelerated oxidative environment, with each week of testing equivalent to approximately one year of real world use in a large-frame combustion turbine, although there are many factors in actual use that could affect oil longevity. TOVT was designed so that samples could be analyzed throughout the test to evaluate the fluid’s condition.

TOVT Conditions

• A 350-ml sample of new turbine oil is placed in glass test cell containing steel/copper wire catalyst conforming to ASTM D5846 specification.

• Test cell – containing oil and catalyst – is placed in 120°C solid block temperature bath and allowed to equilibrate to 120°C for 20 minutes.

• After equilibration, dry atmospheric air is bubbled through the oil at a rate of 3L/hour throughout duration of test.

• Sample is subjected to these aging parameters for up to 18 weeks.

• After required aging time has expired, oil sample is immediately decanted from test cell and allowed to sit undisturbed for three days prior to analysis.

Endure Turbine Oil Controls

Degradation Byproducts

Most Turbine Oils Have Not Been Optimized to Resist Deposit Formation

Most turbine oils have been designed around oxidative stability and longevity; thus, have not been optimized to resist deposit formation. Because of this, formulators have moved toward highly refined base oils, which are oxidatively more stable but have lower solvency power. This results in higher potential for insoluble varnish and sludge formation. LE designed Endure Turbine Oil to control the formation of degradation deposits. One of the ways this was accomplished was using a base oil blend that has the solvency power to ensure solubility of any degradation products that form, without sacrificing oxidative stability.

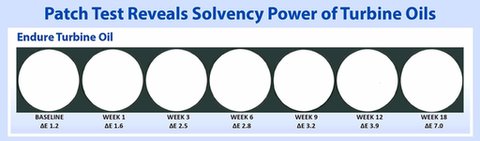

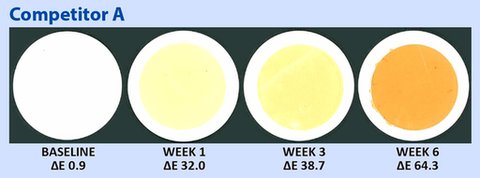

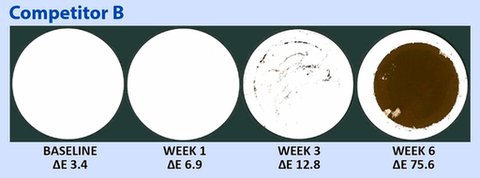

The Membrane Patch Colorimetry test measures the amount of insoluble degradation deposits of in-service turbine oils.

MPC Conditions

• Insoluble deposits are extracted from in-service oil using nitro- cellulose membrane filter (0.45-micron pore size).

• Patch color is analyzed using spectrophotometer, and results are reported as ΔE value.

• MPC ΔE value is used to show insoluble deposits present in turbine oil, and potential for varnish forming on critical surfaces.

Suggested critical ranges for MPC ΔE values are:

• 0-15 – Normal• 15-30 – Continue to monitor

• 30-40 – Abnormal; varnish might be present

• >40 – Critical; varnish is most likely forming on critical surfaces

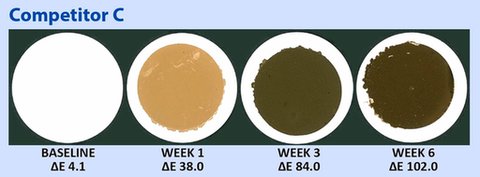

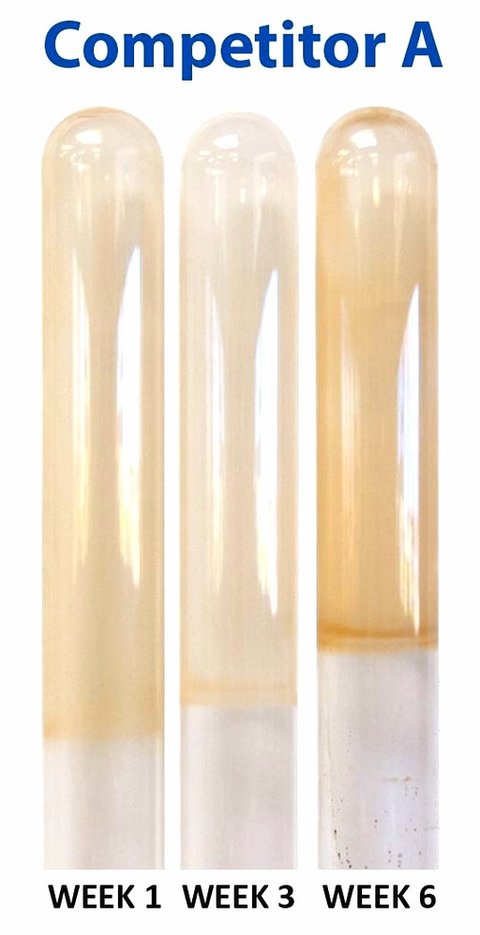

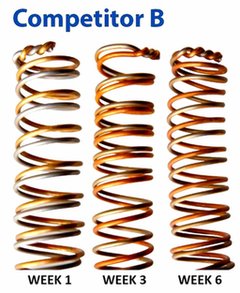

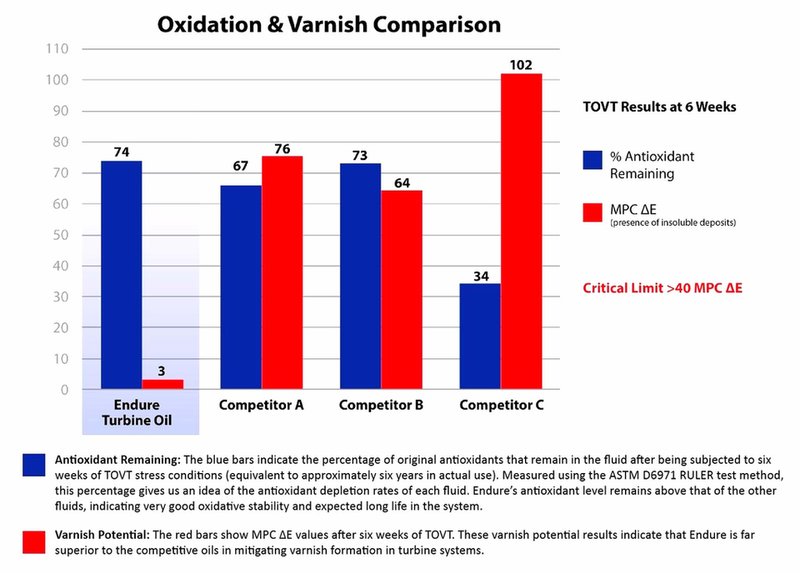

The MPC ΔE values of Endure and competitive turbine oils were measured after being subjected to TOVT conditions for one to 18 weeks. All three competitor oils exhibited MPC ΔE values greater than 40 after six weeks, indicating they contained critical levels of insoluble deposits.

Endure Turbine Oil Protects

Against Varnish

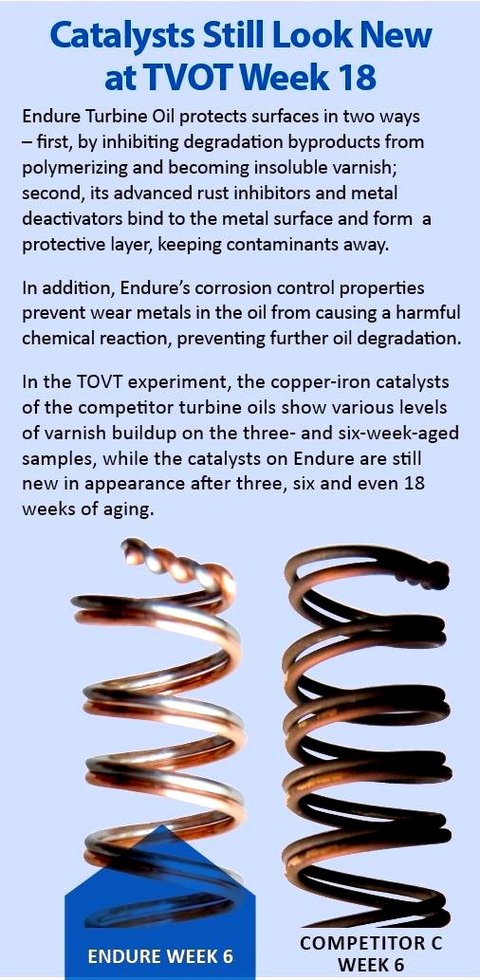

As increasing levels of oxidative and thermal degradation byproducts, as well as degraded additives, form in the turbine oil, they begin to coalesce into larger molecules, which are insoluble in turbine oil. These insoluble degradation products start to plate out as varnish in the turbine system. The photographs below show the TOVT glass vessels of Endure Turbine Oil vs. three major brand competitive turbine oils. The Endure results indicate zero varnish on the TOVT vessels after 18 weeks of stress testing, whereas all three competitors show significant levels of varnish after just six weeks of stressing.

Endure Turbine Oil Protects

Metal Surfaces

Highly Effective vs. Varnish, Rust, Corrosion, Contamination

Insoluble degradation byproducts tend to be polar molecules; therefore, they are attracted to metal surfaces, eventually forming varnish on turbine system surfaces. The biggest problem with turbine oils producing varnish is when the varnish affects valve performance in critical control systems. Varnish buildup on control system valves can cause valves to operate sluggishly or stick completely, resulting in costly skipping, failure to start and shutdowns.

Endure Turbine Oil Protects

Gas Turbines

Keys to Turbine Oil Performance

Oxidation Stability

As the turbine oil is subjected to the stressful operating environment of a turbine system, the oxidative resistance of the fluid diminishes, which in turn increases the potential for varnish and sludge formation. Oxidation stability of the turbine fluid is not determined by the total quantity of antioxidants that are in the turbine fluid (or how large the TOVT test data is), but rather the depletion rate of the antioxidant in the fluid. See blue bars in graph.

Deposit Resistance

The second key factor in determining how well a turbine oil will perform in use is the ability of the fluid to inhibit deposit formation. As explained previously, varnish deposits and sludge buildup result from base oil oxidation and degradation, additive degradation, and low base oil solvency power. No matter how great the oxidative stability of the turbine fluid, if it cannot effectively manage varnish and sludge formation, turbine issues will begin to occur well before the fluid reaches end-of-life conditions. See red bars in graph.

Find your Lubrication Engineers international distributor