OSi provides OFS models to suit nearly every CEMS, or process control application in power plants, refineries, chemical plants, incinerators, air/gas handling systems. Our patented scintillometry measurement technique offers all our systems these advantages:

- Full-path averaging

- Non-intrusive, with no direct contact to flow

- No moving parts, and no calibration required

- Unaffected by distance, pressure, moisture or opacity

- No flow media high temperature limits

- Continuous self-testing & diagnostics

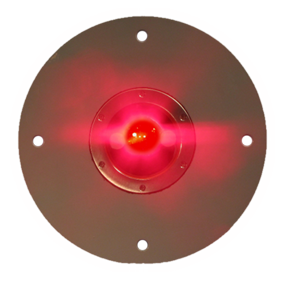

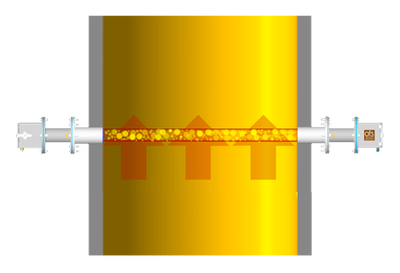

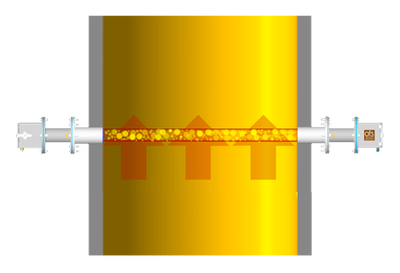

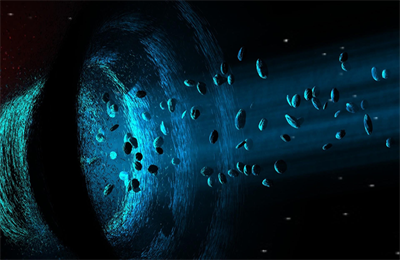

Non-Intrusive

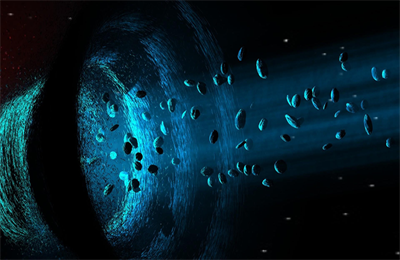

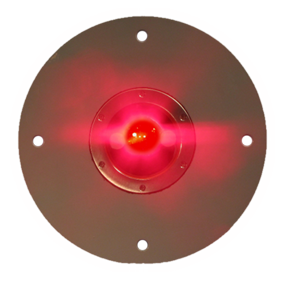

No direct contact with flow media.Immune to the effects of temperature, gas density, moisture content, particulate count, or pressure. If OFS 2000 can detect turbulence-induced fluctuations with even a fraction of the light, it can accurately measure the flow velocity. It is, in this sense, a “pure” measurement.

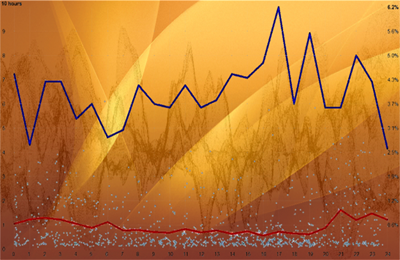

No Calibration Required

Using scintillation as a basis of measurement means the all-digital / DSP-based OFS 2000 systems require no calibration – ever. Our patented process is supported with over 20 million hours of observation data, and certified by NIST (National Institute of Standards.) Automatic calibration check along with continuous self-test diagnostics are built-in for user security.

Full-Path Averaging

OFS 2000 provides a dynamic velocity measurement of the passage of gas or air through a light beam averaged directly across the entire volume. Scintillation through the entire path is detected, analyzed, calculated, and reported - a much more representative measurement than single point or slanted path.

Measures Volumetric Flow

Along with superior accuracy, OFS 2000 can also be configured with the ability to accept smart temperature and pressure sensor current loop data to calculate and report volumetric flow or mass flow in addition to velocity.

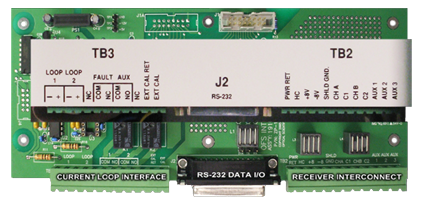

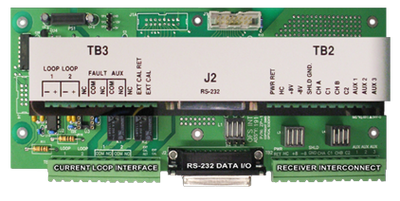

Measurement Reporting By

- 4-20mA Current Loop

- RS 232/485

- ModBus RTU

- Network/Fiber Optic Connectivity

Measurement Not Affected By

- Distance

- Pressure

- Temperature

- Gas Density

- Moisture

- Opacity

Measurement Not Dependent On

- Differential pressure

- Design DP

- Beta ratio

- Temperature

- Gas composition

- Humidity

- Speed of sound

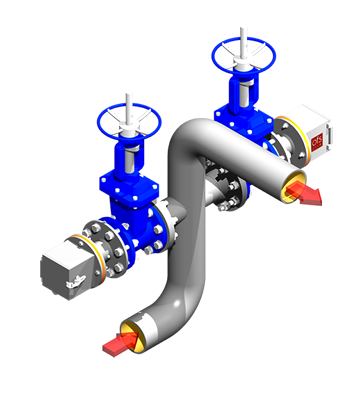

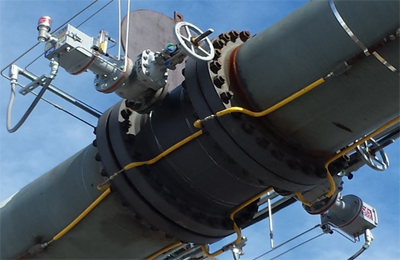

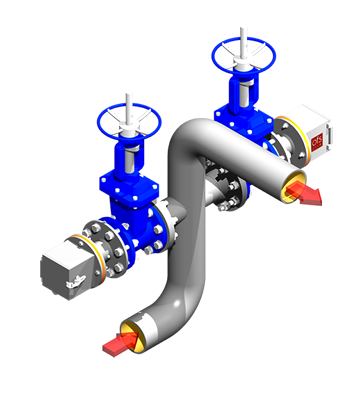

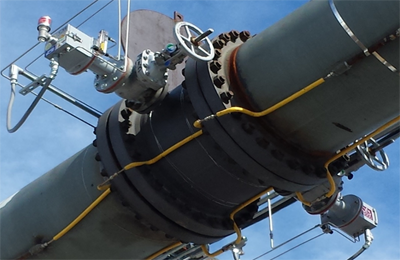

Flexible Installation

OFS can install in tight spaces with minimum space requirements of 2 upstream / 1 downstream diameters. No re-piping needed. Installation is to standard ANSI pattern 4” pipe flange. OFS can be installed on live process pipes using hot tap procedure and gate valves for isolation. No shutdown or interruption required.

Flexible Communication

All systems are equipped with analog current loop / digital data outputs, and can be configured with Serial port, Limited Distance Modem, and Fiber Optic Interface for any type of WAN or LAN.

No Moving Parts

OFS 2000 is essentially maintenance-free, save for window cleaning. OFS internal monitoring alerts the user if window cleaning is required. (Typically only semi-annually (if then) on the dirtiest stack and duct applications.)

Assures Compliance

All OFS 2000 sensors meet or exceed requirements set by the Environmental Protection Agency, and California’s South Coast Air Quality Management District.

EPA Method 14

EPA MACT RSR 40 CroFR 63.670

EPA 40 CFR part 60 & 75

EPA 40 CFR part 60 sub part J & Ja

SCAQMD rule 1118

World Wide Customer Support

OSI has representatives/resellers in North America, South America, and in every quarter of the globe. Click on the links below to find one near you.

Optical Scientific, Inc.

2 Metropolitan Court

Suite 6

Gaithersburg, MD 20878 USA

Tel: +01 301 963 3630

Fax: +01 301 948 4674

E-mail: infofpt@opticalscientific.com

OSi provides OFS models to suit nearly every CEMS, or process control application in power plants, refineries, chemical plants, incinerators, air/gas handling systems. Our patented scintillometry measurement technique offers all our systems these advantages:

- Full-path averaging

- Non-intrusive, with no direct contact to flow

- No moving parts, and no calibration required

- Unaffected by distance, pressure, moisture or opacity

- No flow media high temperature limits

- Continuous self-testing & diagnostics

Non-Intrusive

No direct contact with flow media.Immune to the effects of temperature, gas density, moisture content, particulate count, or pressure. If OFS 2000 can detect turbulence-induced fluctuations with even a fraction of the light, it can accurately measure the flow velocity.

It is, in this sense, a “pure” measurement.

No Calibration Required

Using scintillation as a basis of measurement means the all-digital / DSP-based OFS 2000 systems require no calibration – ever. Our patented process is supported with over 20 million hours of observation data, and certified by NIST (National Institute of Standards.) Automatic calibration check along with continuous self-test diagnostics are built-in for user security.

Full-Path Averaging

OFS 2000 provides a dynamic velocity measurement of the passage of gas or air through a light beam averaged directly across the entire volume. Scintillation through the entire path is detected, analyzed, calculated, and reported - a much more representative measurement than single point or slanted path.

Measures Volumetric Flow

Along with superior accuracy, OFS 2000 can also be configured with the ability to accept smart temperature and pressure sensor current loop data to calculate and report volumetric flow or mass flow in addition to velocity.

Measurement Reporting By

- 4-20mA Current Loop

- RS 232/485

- ModBus RTU

- Network/Fiber Optic Connectivity

Measurement Not Affected By

- Distance

- Pressure

- Temperature

- Gas Density

- Moisture

- Opacity

Measurement Not Dependent On

- Differential pressure

- Design DP

- Beta ratio

- Temperature

- Gas composition

- Humidity

- Speed of sound

Flexible Installation

OFS can install in tight spaces with minimum space requirements of 2 upstream / 1 downstream diameters. No re-piping needed. Installation is to standard ANSI pattern 4” pipe flange. OFS can be installed on live process pipes using hot tap procedure and gate valves for isolation. No shutdown or interruption required.

Flexible Communication

All systems are equipped with analog current loop / digital data outputs, and can be configured with Serial port, Limited Distance Modem, and Fiber Optic Interface for any type of WAN or LAN.

No Moving Parts

OFS 2000 is essentially maintenance-free, save for window cleaning. OFS internal monitoring alerts the user if window cleaning is required. (Typically only semi-annually (if then) on the dirtiest stack and duct applications.)

Assures Compliance

All OFS 2000 sensors meet or exceed requirements set by the Environmental Protection Agency, and California’s South Coast Air Quality Management District.

EPA Method 14

EPA MACT RSR 40 CFR 63.670

EPA 40 CFR part 60 & 75

EPA 40 CFR part 60 sub part J & Ja

SCAQMD rule 1118

World Wide Customer Support

OSI has representatives/resellers in North America, South America, and in every quarter of the globe. Click on the links below to find one near you.

Optical Scientific, Inc.

2 Metropolitan Court

Suite 6Gaithersburg,

MD 20878 USA

Tel: +01 301 963 3630

Fax: +01 301 948 4674

E-mail: infofpt@opticalscientific.com