Company Insight

Sponsored by PROMECON

Industry in flow: turning gas streams into performance and profit

Main video supplied by Transport for London/Image Bank Film via Getty Images

Company Insight

Sponsored by PROMECON

Industry in Flow: Turning Gas Streams into Performance and Profit

TowHaul Corporation is the leading manufacturer of off-road lowboys specifically designed for the open-pit mining industry

Main image credit:

Coal-fired and industrial power plants still provide indispensable baseload electricity and process steam. As renewable generation expands and grid volatility increases, these assets must adapt—boosting flexibility, efficiency, and environmental performance to remain competitive. A robust gas flow analysis is pivotal to that evolution: it uncovers air and flue-gas distribution issues, aligns fuel–air ratios for stable combustion, and reduces unburned carbon and NOx. By detecting maldistribution, leaks, and blockages across ducts, mills, burners, air preheaters, and SCR/FGD trains, operators can cut pressure losses and fan power, prevent slagging, fouling, and erosion, and protect downstream equipment. Accurate flow insight enables faster and safer load changes, lower minimum load, improved heat rate, and consistent emissions compliance—ultimately reducing operating costs while raising reliability and availability.

Caption. Credit:

PROMECON process measurement control GmbH is a German engineering company specializing in advanced measurement systems for process gases in thermal industries. Founded in 1995 in Barleben near Magdeburg, the company has grown from a small start-up into an internationally respected supplier for power, cement, and steel plants. From the beginning, PROMECON set itself apart by developing the first industrial digital flow measurement using cross-correlation, revolutionizing the way industrial gas flows are measured.

Power – The Core Business

Among its three major business segments—Power, Cement, and Steel—the Power sector represented the foundation of PROMECON’s expertise and growth. The company’s measurement solutions are designed to increase efficiency, reduce emissions, and improve reliability in thermal power generation, including coal-, biomass- and waste-fired plants.

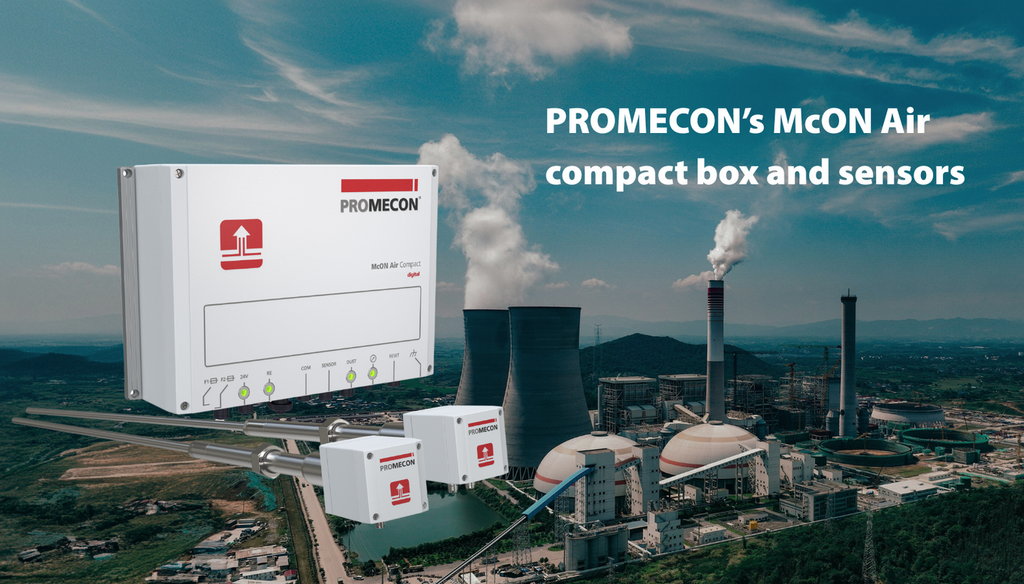

At the heart of this segment stands McON Air, a state-of-the-art digital gas flow measurement system for hot and dusty gases. McON Air measures gas velocity using cross-correlation technology without the need for differential pressure or pitot tubes. The system operates reliably in environments up to 1,000 °C and eliminates maintenance-prone components that typically fail under such extreme conditions. By providing real-time and drift-free data, McON Air allows plant operators to optimise air and flue-gas distribution, stabilise combustion, and minimise fan power consumption.

The benefits are measurable: higher boiler efficiency, lower auxiliary energy demand, and improved process control. The system’s robustness and simplicity make it ideal for retrofit and upgrade projects where existing instruments cannot handle hot, particle-laden gas flows. As PROMECON emphasizes, McON Air helps customers “run their process better and more effectively” by delivering accurate data that drives optimized control loops and operational stability.

Complementing this technology is MECONTROL Coal, a specialized measurement system for pulverized-coal pipes to determine the true mass flow of coal in each burner line. With this data, operators can balance burner loads, stabilise combustion, and improve overall heat balance in the boiler. Uneven fuel distribution is one of the main causes of efficiency losses and emissions in coal-fired plants; MECONTROL Coal eliminates this problem with real-time monitoring.

Together, McON Air and MECONTROL Coal form the backbone of PROMECON’s Power solutions. They enable utilities to lower emissions, increase fuel efficiency, and extend plant life—while achieving faster return on investment through improved operational performance. In an industry transitioning toward decarbonization, PROMECON’s technology provides critical tools for managing combustion more precisely, using alternative fuels, and maintaining efficiency even as load patterns change.

Cement – Optimizing energy-intensive processes

The cement industry faces similar challenges of energy efficiency and emissions control. PROMECON’s systems are used in preheater towers, kilns, clinker coolers, and process fans—key areas where hot, dusty gas flows determine product quality and energy consumption.

By applying McON Air measurement technology, cement producers can precisely monitor air and exhaust-gas flows. This allows them to balance combustion air, reduce fan power, and stabilise kiln operation.

With hundreds of installations worldwide—PROMECON has become a trusted technology partner for process optimization in the cement industry.

Steel – Measurement in harsh industrial environments

In the steel and smelting sectors, PROMECON’s measurement systems are applied in furnaces, converters, and exhaust-gas systems. These environments involve extremely high temperatures, aggressive dust loads, and rapid flow changes—conditions under which conventional flow-measurement devices often fail.

PROMECON’s digital cross-correlation sensors enable operators to optimise furnace control and reduce energy losses. For steel producers under pressure to decarbonise and cut energy costs, these systems support better combustion control, efficient use of secondary fuels, and improved process stability.

Innovation and vision

As industries worldwide pursue higher energy efficiency and lower emissions, the demand for reliable process measurement continues to grow. PROMECON’s technology enables its customers not only to comply with environmental standards but also to achieve significant operational improvements. The company’s instruments turn invisible gas flows into actionable process data—making industrial plants cleaner, safer, and more efficient.

Every product is developed with the goal of delivering robust, maintenance-free performance in extreme industrial conditions. The company’s approach combines precise digital measurement, intelligent signal processing, and practical field experience. By replacing mechanical or pressure-based sensors with solid-state digital systems, PROMECON eliminates common failure points and maintenance costs, allowing customers to focus on production rather than instrumentation.

Outlook

After three decades of innovation, PROMECON remains at the forefront of process-gas measurement technology. From its base in Germany, it serves customers across Europe, the Americas, Asia, and the Middle East.

Looking ahead, PROMECON continues to expand its expertise into new fields, including renewable-energy processes and carbon-capture applications. Yet the mission remains unchanged: to provide precise, maintenance-free measurement solutions that empower industrial operators to run their processes faster, better, and more efficiently.

In an era defined by efficiency, sustainability, and digital transformation, PROMECON stands as a trusted partner for measurement excellence—delivering innovation made in Germany to the world’s most demanding industries.

Contact information

PROMECON process measurement control GmbH

Tel: +49 39203 512-250

Email: sales@promecon.com

Web: www.promecon.com