IoT technologies have been widely adopted across the energy sector. Energy companies are under continuous pressure to tech-enable their assets at every step of the value chain to ensure consistent production schedules, quality, and optimised production costs.

According to GlobalData's Q2 2023 Tech Sentiment Polls, 48% of poll respondents believe that IoT is already tangibly disrupting their industry. This highlights the wide adoption of this theme across all sectors.

Installing IoT devices such as sensors and probes to enhance data collection from power stations, energy grids, oil rigs, energy storage facilities, and refineries is a critical part of this industry's digital transformation. This highly process-driven approach naturally lends itself to the integration of adjacent technologies, such as AI and cloud computing, to assist with the analysis and storage of the collected data, enhancing the decision-making process.

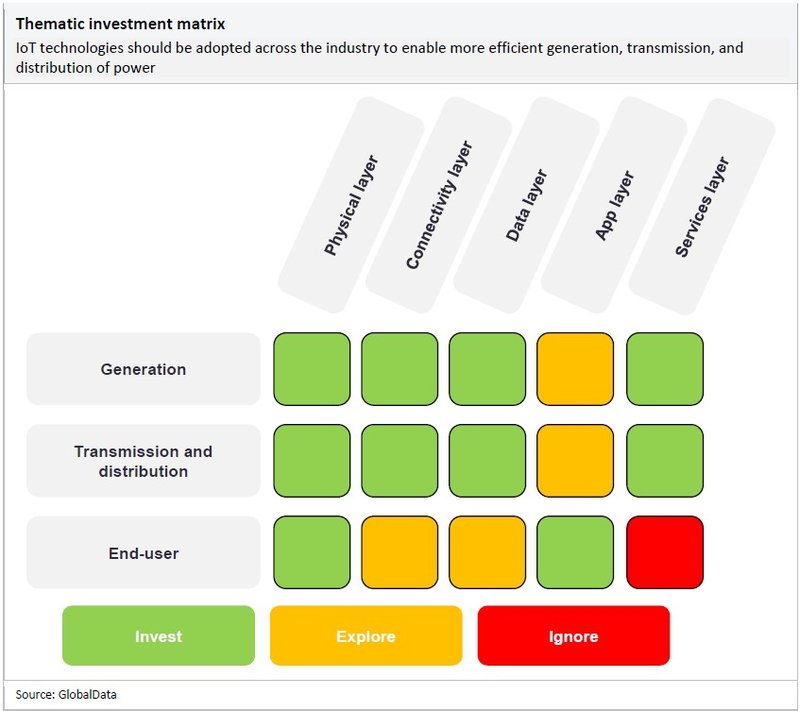

The matrix below details the areas in IoT where companies operating in the energy sector should focus their time and resources. We suggest that energy companies invest in technologies shaded in green, explore the prospect of investing in technologies shaded in yellow, and ignore areas shaded in red.

Addressing the industry challenge of aging infrastructure through IoT innovation

IoT investments should be targeted at solving specific problems. Integrating IoT sensors, in combination with adjacent technologies such as digital twins and AI, into energy sector infrastructure will enable predictive maintenance and greater control over the monitoring of operations, particularly at remote sites. Predictive maintenance tools, based on real-time data collection through IoT sensors and devices, can act intelligently, detect anomalies, and help to maintain efficiency. Through this, IoT sensors can replace the need for humans in damage assessments and implement remote maintenance measures much more effectively.

Energy systems such as wind and solar are most productive when operating without any unexpected repairs of parts, such as bearings, rotating elements, lubrication systems, etc. Predictive maintenance enables companies to minimise production risk by eliminating unforeseen outages. Enterprise-level utilisation of IoT technology solutions can help companies collect a significant amount of data for a maintenance schedule without altering their regular production practices. This will, in turn, help power companies reduce operational costs and improve operational efficiencies along with profitability.

In the case of wind turbines, IoT sensors can retrieve data about the electricity that passes through the blades when lightning strikes a turbine. The sensors can also help measure a turbine’s performance, aid the real-time data flow to the control system and send alerts. This can help to warn companies of issues ahead of time, such as, for example, by warning them about a turbine blade needing a replacement before a serious failure occurs.

Mitigating the risks of energy security using IoT

Energy companies can take advantage of smart metering in their operations and collate data through IoT-enabled connected devices to help reduce the risks of security in their energy supply chains. IoT devices such as smart meters, when paired with machine learning (ML) algorithms, can be integrated into energy systems or national grids and used to monitor and provide live data feedback on energy production patterns and demand trends.

This industry's use of IoT technology will become critical in reducing the risks of sudden geopolitical energy stresses on regional energy supplies, as well as helping to integrate inconsistent renewable energy sources. Overall greater adoption of these technologies will help to mitigate the risks of power shortages or overwhelmed grid connections.

For many consumers when choosing an energy provider, particularly following the fuel crisis in late 2022, the reliability and affordability of electricity supplies are at the heart of their decision-making process. IoT-based energy management systems connect customers to a smart grid, offering them greater control over their energy consumption and its associated costs. This also helps to increase awareness of the importance of choosing low carbon energy sources. Consumers can be informed in real-time when the most efficient times to use energy are and be rewarded at times of low grid-stress or higher renewable generation. Also, consumers and businesses who opt to install renewable energy sources, such as solar panels, to power their properties can track these financial and energy transactions through their smart connected devices.

IoT enables ongoing data analysis to monitor decarbonisation

Reducing the carbon footprint of operations, even within the oil and gas sector, is a core challenge faced by most companies within the energy sector. Companies are beginning to be held accountable for their Scope 1 emissions, and there is a pipeline of regulation that could introduce Scope 3 monitoring. IoT helps companies to save money and aids in evaluating ESG risks. The data collected from IoT-connected devices such as sensors, can be used to monitor a wide range of variables related to operational efficiency, energy demand, and environmental factors such as air and noise pollution.

The integration of IoT devices for the collection of this information can enable ongoing analysis and adjustment of the operations and plant running to minimise the risk of business disruption, improve resource management, extend the life of infrastructure and assets, and even help transition energy supplies to encourage renewable integration into the grid.

IoT devices can also collect scientific data to support environmentally friendly initiatives. The data collected related to greenhouse gas (GHG) emissions can be used to assess progress towards carbon goals and therefore help demonstrate transparency in how a business monitors its initiatives.

Predictive analytic tools that use this collected data can be deployed to help energy sector companies plan their ESG initiatives and guide their actions toward these. This can be achieved using the underlying AI-based predictive maintenance algorithms that can detect potential equipment failures, thereby preventing production shutdowns. This in turn can help companies to devise more sustainable operations for their power plants, while mitigating untoward mishaps.

IoT can help with data management during the energy transition

The global focus on CO2 reduction is driving progress towards a more sustainable world, as electrical grids and renewable power sources become critical infrastructures within society. Reducing anomalies and service interruptions and safeguarding electricity grids during this transition is essential for the energy sector, and IoT and AI predictive tools are critical in maintaining the resilience of national grids.

IoT devices, connected to the cloud, have been adopted by transmission system operators and hardware manufacturers throughout the sector. Software equipped with AI is allowing for easier and faster real-time analysis, of the data collected, for device maintenance. Companies are using remote terminal units, an electronic remote-control device that allows communication between the elements of the grids and the distributed control software. This is helping companies prevent critical issues by monitoring real-time data and reducing maintenance costs.

Digital twins are also gaining importance for the proactive management of power grid assets during the global energy transition. A digital twin is an up-to-date digital representation or model of a physical asset in operation on a power grid. It reflects the current asset condition and includes relevant historical data.

Digital twins can be used to evaluate the current condition of the asset using data collected by IoT sensors and devices, and more importantly, predict future behaviour, refine the control, or optimise operation by performing periodic (offline) or continuous (online) equipment condition monitoring. The integration of AI into these digital twins is essential for helping to manage and process the data feed supplied by the IoT network and predict the most appropriate action to be taken to mitigate risks and inefficiencies.

GlobalData, the leading provider of industry intelligence, provided the underlying data, research, and analysis used to produce this article.

GlobalData’s Thematic Intelligence uses proprietary data, research, and analysis to provide a forward-looking perspective on the key themes that will shape the future of the world’s largest industries and the organisations within them.