Determining Temperature Class for Electric Process Heaters

/ Electric process heaters that interact with flammable materials in explosive environments need safeguards to protect the equipment against catastrophic failures. /

THERE ARE SEVERAL POSSIBLE PROTECTION METHODS THAT MAY BE EMPLOYED TO PROTECT AN APPLICATION FROM A POTENTIAL EXPLOSION. A TEMPERATURE CLASS REQUIREMENT WILL BE PROVIDED BY THE USER BASED ON THE EXPLOSIVE GASES THAT MAY BE PRESENT IN THE INSTALLATION AREA. THE MAXIMUM SURFACE TEMPERATURE OF THE PROCESS HEATER MUST THEN BE EVALUATED TO ASSURE COMPLIANCE.

Temperature classes that are based on the maximum operating temperature for heaters prescribe the level of safeguards. Determining the temperature class for a specific electric process heater is unique compared to other electrical components installed in classified locations. The temperature code, or T-code, is highly dependent on the process conditions of the heating application. Some end users may believe and request that the temperature classification be based solely on the temperature of the terminal enclosure. However, current standards for the general requirements of equipment to be installed in explosive atmospheres state that an external source of heating must be considered in the product evaluation.

If end users do not factor in temperatures from the flange to the electrical termination, the wrong T-code could be used, which could mean a heater may not be properly certified and fail inspection thereby increasing delays and costs for end users.

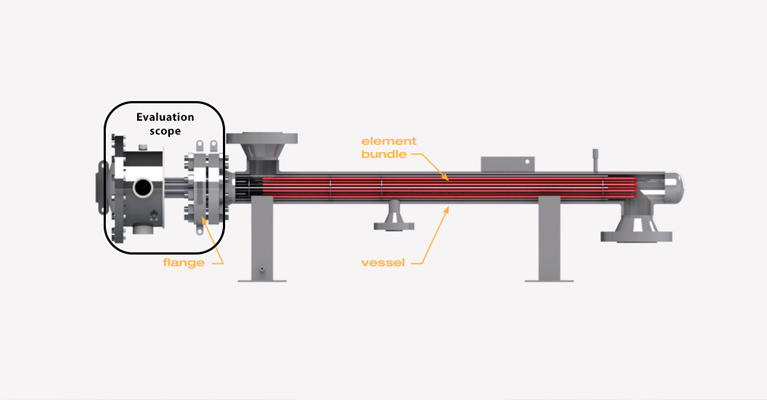

DEFINITIONS & ENVELOPE BOUNDARY

The first step is to understand the primary definitions and envelope boundary for the temperatures of interest.

Per EN/IEC 60079-0, Section 3, Terms and Definitions

Maximum Surface Temperature is the highest temperature which is attained during service under the most adverse conditions (but within the specified operating tolerances) by any part or surface of the heater bundle which is exposed to the atmosphere. NOTE: For electrical equipment in an explosive gas atmosphere, this temperature may occur on an internal component (internal to the enclosure) or on the external surface of the enclosure/heater flange/standoff, etc., depending upon the type of protection employed.

Enclosure Service Temperature is the maximum or minimum temperature reached at specific points of the equipment when the equipment is operating at rated conditions, including ambient temperature and any external sources of heating or cooling.

Enclosure Internal Temperature is the maximum air temperature reached inside the terminal enclosure when the equipment is operating at rated conditions, including ambient temperature and any external sources of heating or cooling.

CERTIFICATION REQUIREMENTS

Next, we need to understand the requirements of the applicable codes which typically are determined by the country where installation happens. North American regulations (NEC Article 500 & CSA C22.2) are different than European regulations (EN 60079-0) as well as International regulations (IEC 60079-0). However, each of these standards specify that influence from an external source of heating must be included in the determination of the maximum surface temperature. For an electric process heater assembly, this means that the heat generated inside the terminal enclosure needs to be considered as well as the temperature of the flange and other exposed surfaces. The temperature impact of this entire area must be included in the evaluation of maximum surface temperature.

Per EN/IEC 60079-0 section 5 references below:

5.1.2 External source of heating or cooling

Where the equipment is intended to be physically connected to or influenced by a separate external source of heating or cooling, such as a heated or cooled process vessel or pipeline, the ratings of the external source shall be specified in the certificate and in the manufacturer’s instructions.

NOTE 1: The external source of heating or cooling is frequently referred to as the “process temperature.”

NOTE 2: The way in which these ratings are expressed will vary according to the nature of the source and the installation. For sources generally larger than the equipment, the maximum or minimum temperature will usually be sufficient. For sources generally smaller than the equipment, or for heat conduction through thermal insulation, the rate of heat flow may be appropriate. Alternatively, the rating is often expressed by specification of a temperature at a defined accessible point on the equipment.

NOTE 3: The influence of radiated heat may need to be considered on the final installation. See IEC 600079-14

5.3.1 Determination of maximum surface temperature

Maximum surface temperature shall be determined according to 26.5.1 considering the maximum ambient temperature and, where relevant, the maximum rated external source of heating.

PROCEDURE STEPS

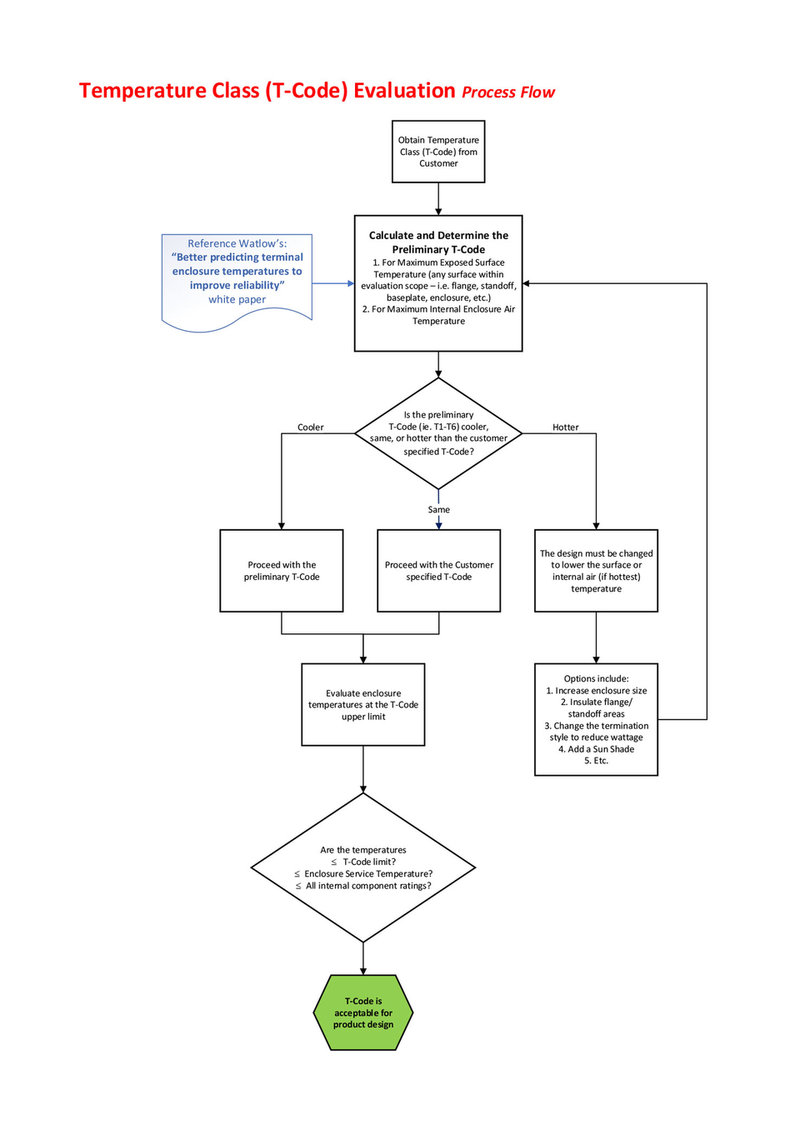

The first step in calculating a preliminary T-code is to determine the maximum surface temperature and internal enclosure air temperature based on the heater design operating in the most demanding conditions while remaining within design specifications. These conditions include: max process temperature influence, full power/amperage operation, max ambient temperature for installation location and solar load if applicable.

As Watlow engineers have proven, the internal enclosure air temperature is impacted by the pins that attach heating elements to the electrical termination. With enough amperage flowing through them, the pins and other electrical supply connections can act as individual “small” heaters and could dramatically increase the temperature within the enclosure (hyperlink to other white paper).

Once the preliminary T-code is determined, electric process heater designers must answer an important question: Is the preliminary T-code cooler, same or hotter than the customer specified T-code? The answer to that question is an important guide in the development of the heater.

If it is cooler than specifications, then proceed with the cooler T-code. If it is the same, then proceed with the customer specified T-code. If the preliminary T-code is hotter, then the proposed design does not meet the customer requirement. At that point, design changes must be considered to meet the customer specified T-code, which is often prescribed by safety regulations for where the heater will be installed.

The last step is to verify that the enclosure service temperature rating will not be exceeded. We are validating that even if the max surface temperature reaches the assigned T-code temperature limit, the enclosure service temperature rating will not be exceeded and all of the internal enclosure components are suitable for the expected worst-case temperatures.

An enclosure running a service temperature in excess of the maximum could cause two problems. If the temperature exceeds internal component ratings, there is a higher chance of component degradation and an increased chance of early equipment failure. Additionally, there is potentially a safety risk as the heater will be operating at service temperatures beyond what it has been rated for. If ignition happens at that elevated temperature, the integrity of the enclosure may fail and not contain an explosive event.

See the entire evaluation process in the flow chart below:

The first step in calculating a preliminary T-code is to determine the maximum surface temperature and internal enclosure air temperature based on the heater design operating in the most demanding conditions while remaining within design specifications. These conditions include: max process temperature influence, full power/amperage operation, max ambient temperature for installation location and solar load if applicable.

As Watlow engineers have proven, the internal enclosure air temperature is impacted by the pins that attach heating elements to the electrical termination. With enough amperage flowing through them, the pins and other electrical supply connections can act as individual “small” heaters and could dramatically increase the temperature within the enclosure (hyperlink to other white paper).

Once the preliminary T-code is determined, electric process heater designers must answer an important question: Is the preliminary T-code cooler, same or hotter than the customer specified T-code? The answer to that question is an important guide in the development of the heater.

If it is cooler than specifications, then proceed with the cooler T-code. If it is the same, then proceed with the customer specified T-code. If the preliminary T-code is hotter, then the proposed design does not meet the customer requirement. At that point, design changes must be considered to meet the customer specified T-code, which is often prescribed by safety regulations for where the heater will be installed.

The last step is to verify that the enclosure service temperature rating will not be exceeded. We are validating that even if the max surface temperature reaches the assigned T-code temperature limit, the enclosure service temperature rating will not be exceeded and all of the internal enclosure components are suitable for the expected worst-case temperatures.

An enclosure running a service temperature in excess of the maximum could cause two problems. If the temperature exceeds internal component ratings, there is a higher chance of component degradation and an increased chance of early equipment failure. Additionally, there is potentially a safety risk as the heater will be operating at service temperatures beyond what it has been rated for. If ignition happens at that elevated temperature, the integrity of the enclosure may fail and not contain an explosive event.

Temperature codes can only prescribe the correct safety precautions for electric process heaters if designers fully take into account all of the heat generated inside and outside the heater enclosure. That includes the maximum surface temperature, the enclosure service temperature and the enclosure internal temperature. Failing to do so could mean an unsafe situation or inspectors not approving safety precautions causing potential cost overruns.

Temperature codes can only prescribe the correct safety precautions for electric process heaters if designers fully take into account all of the heat generated inside and outside the heater enclosure. That includes the maximum surface temperature, the enclosure service temperature and the enclosure internal temperature. Failing to do so could mean an unsafe situation or inspectors not approving safety precautions causing potential cost overruns.

contact information

Watlow Electric Manufacturing company

12001 Lackland Road

Saint Louis, MO 63146

United States

Head Office Europe:

Watlow Plasmatech GmbH

Brennhoflehen-Kellau 156

5431 Kuchl

Austria

T +43 6244 20129 0